Delivering innovation and compliance across carriageway assessments

Effective carriageway condition assessment is an essential part of long-term asset management planning, proactive carriageway maintenance, and the delivery of safer, more efficient road networks. The recent introduction of PAS 2161:2024 presents a generational opportunity for developing industry practices further, and a key feature of PAS 2161 is its flexibility regarding the technologies used for data collection. This approach encourages innovation and enables the integration of new, cost-effective solutions as they become available.

SCANNER+

We utilise state-of-the-art, PAS2161 and UKPMS accredited SCANNER vehicles, which bring together the best in GPS, image-capture, AI analysis, and laser scanning technology to deliver detailed network-wide assessments of carriageway infrastructure.

- 3D data is exactly what we offer, we go beyond simple visual interpretation of the surface condition and utilise sensor technology to provide a 3-dimensional profile of the road surface

- We utilise advanced laser profilers delivering accurate ride quality, texture, rutting, and roughness measurements

- We apply Automatic Distress Detection (ADD) technology, which applies sophisticated

and objective algorithms to the 3D data and image-based AI system, to deliver precise andrepeatable distress measurements

Our SCANNER+ services are designed to harness industry-developments with PAS 2161, providing Clients with the tools and freedom to drive local asset management practices. Our enhanced services deliver:

- UKPMS & PAS 2161 compliant national data reporting

- Maintenance scheme identification & prioritisation

- Condition projection modelling

- Data visualisation and embedded video

- Added-value datasets to support maintenance decisions including enhanced cracking, potholes, patching, edge defectiveness, ravelling, line markings and more

Annual Engineers Inspections (AEI)

The fundamental principle of the Annual Engineers Inspection (AEI) is that the survey is undertaken by a competent Highway Engineer experienced in treatments and materials. AEI, which is aligned with PAS 2161, covers a wide range of highway maintenance remedies including basic maintenance, preventative and preservative measures, and resurfacing or reconstruction works. Prior to delivering an AEI survey, our Engineers hold a client workshop to understand:

- What treatments are used within the authority?

- What maintenance interventions are used?

- What are the unit rates in delivering the treatments?

- What should be collected to inform a prioritisation process?

This client focused approach ensures maximum value can be derived from the survey and AEI delivers a better reflection of maintenance need than other defect based surveys.

Benefits of undertaking an AEI include:

- Network-level and highly efficient survey methodology

- Obtain PAS compliant condition categories to support national reporting

- Engineering-led multi-year costed works programmes can be delivered

- Projection modelling provides more accurate year-on-year comparisons of network condition

- Value management workshops tailor services to your asset management needs and corporate objectives

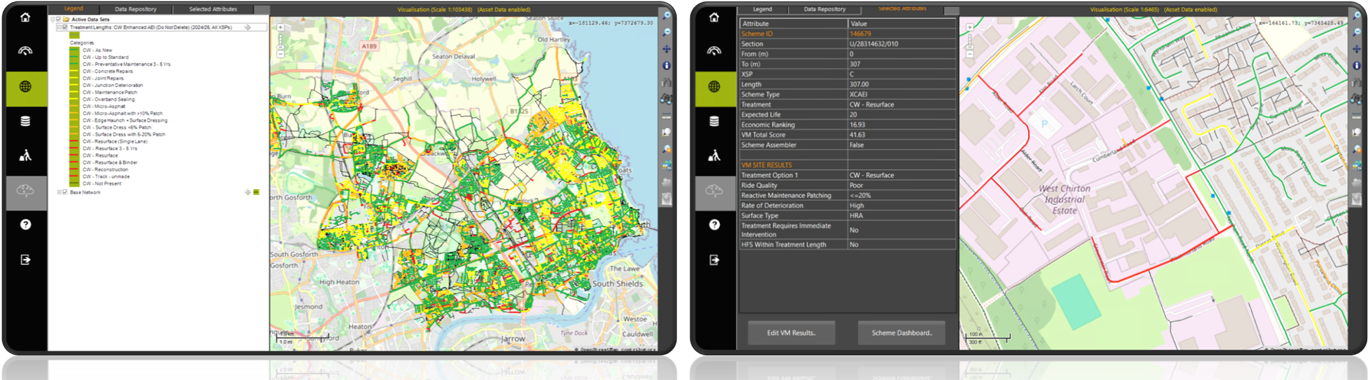

- AEI results integrate seemlessly with our XA© Scheme Assembler software module

Infrastructure Vision (iV) 360° Surveys

XAIS-PTS Infrastructure Vision (iV) 360° surveys are transforming the way local authorities collect, store, and analyse the condition of carriageways. We combine high-definition photographic imagery, LiDAR, 3D mapping technology, and machine learning, to provide our clients with a comprehensive understanding of carriageway defectiveness. Through industry-leading and accredited asset management software and our extensive engineering expertise, we make infrastructure monitoring, auditing, planning and maintenance more sustainable, cost-effective and safety focused.

Survey benefits include:

- Traffic-speed assessment designed to assess your full network heirarchy

- Access and interrogate detailed defect information alongside imagery through our web-viewer XA© Explorer

- Receive fully costed and prioritised works programmes

- Enhance carriageway condition assessments through embedding iRAP safety assessments, which are obtained using the same iV 360° technology - iRAP supports a more holistic view of highway maintenance by accounting for more than carriageway condition alone

UKPMS Coarse & Detailed Visual Inspections

Course Visual Inspections (CVI) are driven surveys that collect information on the condition of your carriageways. Standard defects assessed include wearing course and surface deterioration, cracking, rutting, edge deterioration, and more. The survey was developed by asset management experts to be a highly efficient and cost-effective network level assessment.

Detailed Visual Inspections (DVI) are undertaken on foot by a UKPMS accredited inspector using a hand-held data collection device and calibrated measurement wheel. Inspectors assess condition using an extensive defect catalogue referenced by surface material type including fretting, cracking, chip loss, cracked and depressed flags, and joint defectiveness to name a few examples.

We are the UKs leading provider of UKPMS surveys and our highly-experienced accredited inspectors utilise the latest hand-held data capture devices alongside our UKPMS accredited XA© Inspector software.

Asset management support services

We are also an industry-leader in UKPMS and asset management solutions, and our experienced consultancy team will work with you to provide an end-to-end service. We deliver a variety of industry-standard and bespoke reports including but not limited to:

- Automatic Pass

- BVPI 224b & BVPI 187 reporting

- PAS 2161 reporting

- Maintenance scheme recommendation

- Value management workshops to support scheme prioritisation

- GIS condition mapping and analysis

Why choose XAIS-PTS?

At XAIS-PTS our team has a wealth of experience, and we deliver comprehensive carriageway survey solutions alongside our wider surveys, software, professional services, programme development & design, materials testing, and certification services.

If you have any questions or queries about our services, please contact us today – our team will be more than happy to have a conversation with you regarding your project requirements!